Why Medium Voltage Power Systems Need Specialized Contractors

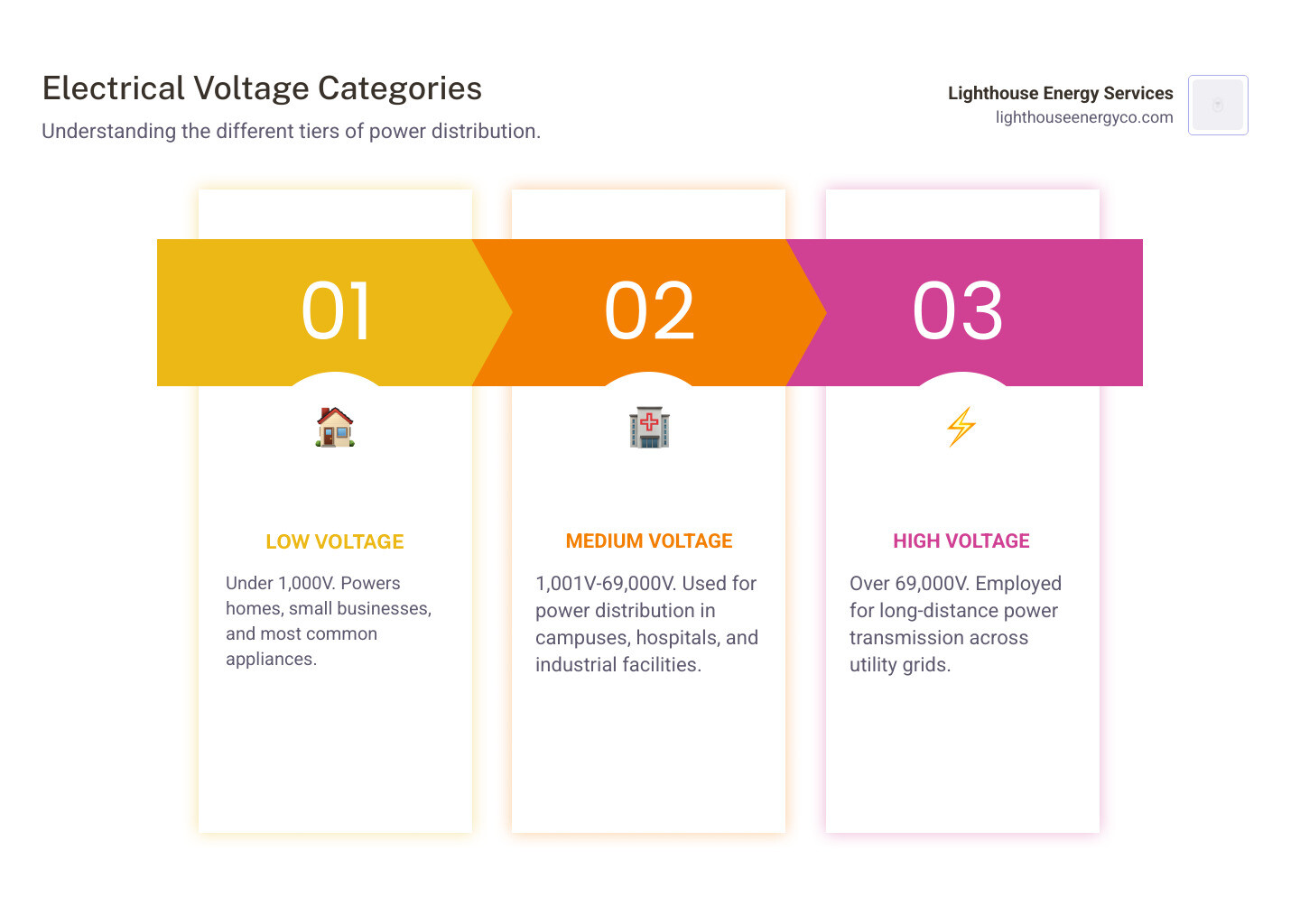

Medium voltage electrical contractors are specialized professionals who design, install, maintain, and repair electrical systems operating between 1,001 volts and 69,000 volts (69kV). Here’s what you need to know:

Key Facts About Medium Voltage Electrical Contractors:

- Voltage Range: They work with systems between 1kV and 69kV – higher than standard building power (480V) but lower than utility transmission lines.

- Specialized Training: Technicians typically complete 5-year training programs covering cable terminations, system architecture, and safety protocols.

- Primary Services: Installation of underground duct banks, cable splicing and terminations, switchgear installation, preventative maintenance, and 24/7 emergency response.

- Where They’re Needed: University campuses, hospital complexes, manufacturing plants, data centers, and large commercial facilities.

- Why Specialization Matters: Medium voltage systems require special knowledge, certifications, and equipment to operate safely and efficiently – general electricians aren’t qualified for this work.

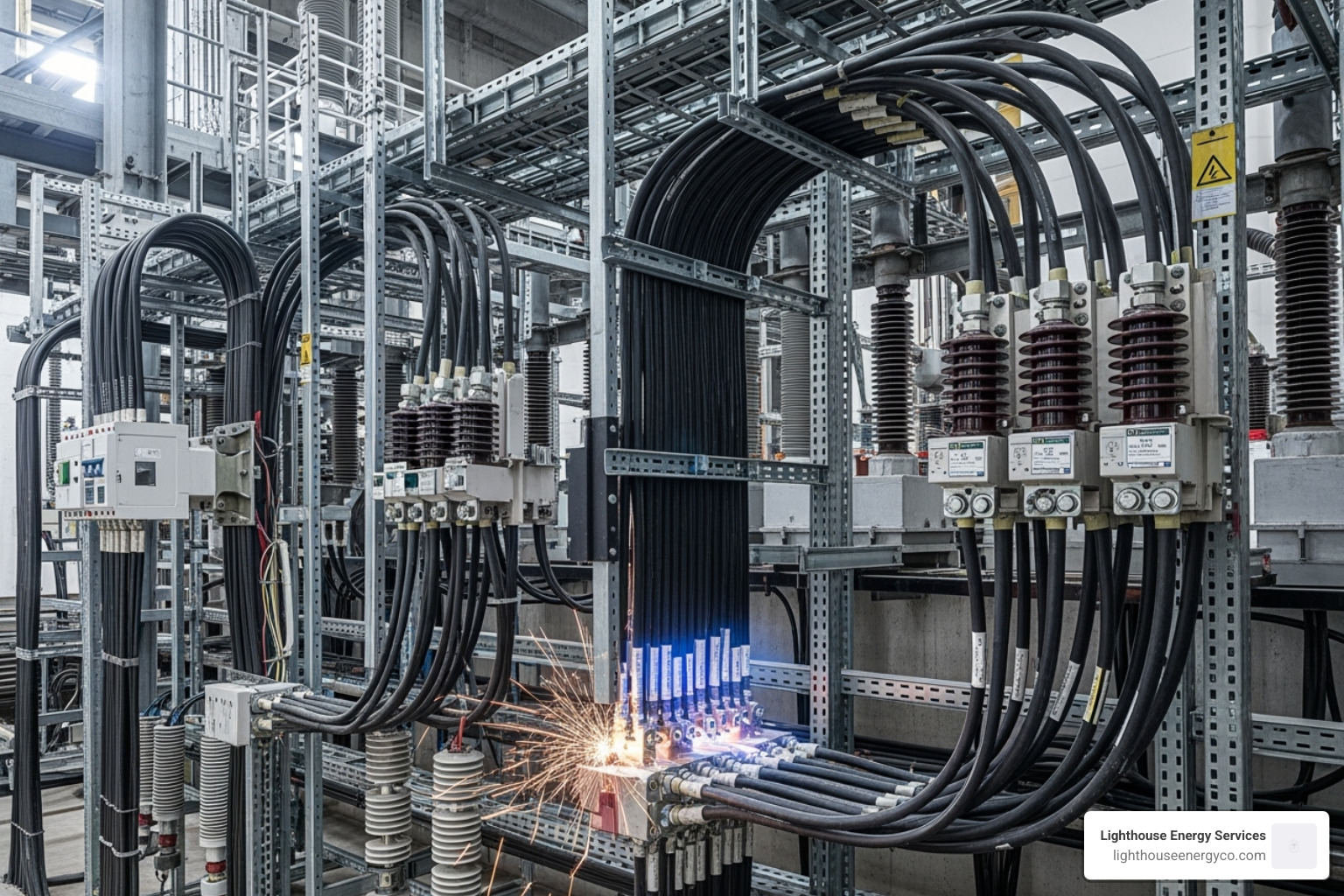

Medium voltage distribution systems are the critical link between high-voltage utility lines and the equipment that powers our modern world, ensuring hospitals and manufacturing plants have reliable electricity. But working with thousands of volts isn’t like changing a light switch. A single mistake can cause catastrophic equipment failure, dangerous arc flash incidents, or costly power outages. This is why specialized contractors exist—professionals who can design, coordinate, and maintain these complex power networks to keep facilities running 24/7.

I’m Bruce Kemp, and with decades of experience as an electrical contractor, I’ve seen why medium voltage electrical contractors require such specialized expertise and the risks facilities take when they cut corners.

Explaining Medium Voltage: The Backbone of Modern Power Distribution

When you flip a light switch, you’re using low-voltage power. That electricity traveled through a complex network of different voltage levels, with medium voltage sitting right in the middle. It’s absolutely critical to how modern facilities get their power.

What is Medium Voltage?

According to ANSI/IEEE standards, medium voltage refers to electrical systems operating between 1,001 volts and 69,000 volts (69kV). This range is significantly higher than your home’s wiring but lower than the massive transmission lines carrying electricity across states.

Think of it this way: high voltage lines bring power to a region, and low voltage powers your office lights. Medium voltage is the critical bridge between the two. It steps down high-power transmission and distributes it efficiently throughout large campuses and industrial facilities. Without it, energy losses would be massive. This is why medium voltage electrical contractors need specialized knowledge to design and build the arterial systems that keep entire facilities running.

Where is Medium Voltage Used?

Medium voltage systems are the unseen backbone of any large facility with heavy power demands. Key applications include:

- University Campuses and Hospital Complexes: These facilities rely on medium voltage for robust, efficient power distribution across multiple buildings, supporting everything from research labs to life-support equipment.

- Data Centers: With thousands of servers and massive cooling systems running 24/7, data centers have enormous power demands that only medium voltage can practically and efficiently meet.

- Manufacturing Plants: Medium voltage powers heavy machinery, from assembly line robots to industrial furnaces.

- Large Commercial Buildings: Shopping centers and large office complexes use it for centralized power distribution.

- Renewable Energy Facilities: Solar and wind farms use medium voltage systems to collect power from individual generators and transmit it to the grid.

In all these applications, reliable power isn’t optional—it’s essential. General electricians lack the training for this complexity, which is why you need professionals who understand the architecture and safety requirements of medium voltage work.

Core Services of Medium Voltage Electrical Contractors

Working with thousands of volts requires years of specialized training and an absolute commitment to safety. Medium voltage electrical contractors like us at Lighthouse Energy are specialists who provide a full range of services for these powerful systems.

Installation and Construction

Building a medium voltage system is a precise process with no room for error. Our installation services include:

- Underground Duct Banks: We construct concrete-encased pathways to protect vital cables from damage.

- Cable Installation: Our teams use specialized equipment to handle and install the heavy-gauge conductors used in medium voltage systems.

- Splicing and Terminations: This highly technical skill involves joining cables and connecting them to equipment. It’s a craft that takes years to master, as a single mistake can lead to catastrophic failure.

- Switchgear and Transformer Setup: We install the core equipment that controls, protects, and steps down voltage for your facility, including modern switchgear with advanced arc flash safety technology.

- Substation Construction: For larger projects, we build the central hubs for power distribution, coordinating all aspects of construction.

For more information on how we keep your electrical systems running smoothly, explore our electrical services.

Maintenance and Repair

Even a perfectly installed system needs regular attention to ensure reliability. Our maintenance and repair services focus on preventing problems before they start.

- Preventative Maintenance: We implement regular inspection schedules to test connections, check insulation, and verify that protective devices are functioning correctly.

- Troubleshooting and Testing: Using specialized equipment, we hunt for subtle signs of degradation that could lead to future failures and perform tests to verify all components operate within specifications.

- Equipment Repair and Replacement: We handle the efficient replacement of faulty cables, worn-out switches, or aging transformers to minimize downtime.

- 24/7 Emergency Service: Electrical emergencies don’t keep business hours, and neither do we. We’re available around the clock to respond when you need us most.

System Testing and Commissioning

Before a new or upgraded system goes live, it undergoes rigorous testing to guarantee long-term reliability.

- Comprehensive Performance Testing: We use advanced diagnostic tools to verify the integrity of every cable, switch, and transformer.

- System Grounding and Switching Checks: We confirm that safety grounding is installed correctly and that switching procedures work as designed, often creating detailed Method of Procedure (MOP) documents for facility managers.

- Commissioning: In the final phase, we energize the system in stages, test it under load, and coordinate with utility companies to ensure seamless integration with the grid.

Quality control is integrated into every phase. When working with thousands of volts, “good enough” is never an option.

The Specialized Expertise Required for Medium Voltage Work

You wouldn’t ask a general practitioner to perform brain surgery, and the same logic applies to your facility’s power systems. The high stakes and complexity of medium voltage electricity demand specialized medium voltage electrical contractors.

Over my years in the industry, I’ve seen the dangerous consequences—from equipment damage to life-threatening arc flash incidents—when facilities use unqualified contractors. This work requires a completely different level of expertise.

Why You Need Specialized Medium Voltage Electrical Contractors

At thousands of volts, electricity can arc across air gaps and generate explosive forces. This reality makes specialized knowledge non-negotiable. General electricians lack the training and tools for this work. Key reasons to hire a specialist include:

- Safety: Specialists understand how to mitigate the extreme dangers of arc flash and high-energy faults.

- Complexity: Medium voltage systems involve intricate engineering, precisely coordinated protective relays, and complex switchgear that require expert configuration.

- Specialized Equipment: This work requires insulated tools, advanced testing equipment, and arc flash-rated PPE that most general contractors don’t own.

- Minimizing Downtime: For facilities like hospitals and data centers, downtime is catastrophic. Specialists design for redundancy and perform maintenance without interrupting operations.

- Reliability and Compliance: Expert contractors engineer solutions that meet and exceed strict regulations, ensuring your system runs reliably for decades.

Essential Skills and Certifications for Medium Voltage Electrical Contractors

Becoming a qualified medium voltage specialist is a years-long journey of continuous learning and hands-on experience. Key qualifications include:

- Intensive Training Programs: The industry standard is a 5-year program covering everything from cable terminations to advanced system architecture and safe shutdown protocols (MOPs).

- Cable Splicing and Termination Skills: This is a specialized craft requiring precision to create safe, reliable connections where mistakes can be catastrophic.

- System Grounding Knowledge: Proper grounding is critical for both safety and ensuring protective devices function correctly during a fault.

- Manufacturer Certifications: Technicians are often certified by manufacturers to install and maintain specific switchgear, transformers, and protective devices.

- Advanced Troubleshooting: Specialists use advanced diagnostic equipment and a deep understanding of power distribution to quickly identify and resolve system faults.

- Safety Standards Compliance: At Lighthouse Energy, our team maintains an unwavering commitment to OSHA safety standards and industry best practices, fostering a culture where everyone goes home safely.

- State Licensing: Contractors must hold appropriate state electrical licenses and often general engineering credentials. We ensure our team stays compliant with all Florida regulations.

At Lighthouse Energy, we invest heavily in our team’s ongoing education to stay ahead of evolving technology and safety protocols. You can learn more about our qualifications on our About Us page. Working with specialists gives you peace of mind that your facility’s power is in expert hands.

Safety and Technology: The Pillars of Modern MV Contracting

Working with thousands of volts is inherently dangerous, which is why our work at Lighthouse Energy is built on two pillars: an uncompromising commitment to safety and the smart use of modern technology. These elements work together, as advanced tech is only effective when paired with rigorous safety protocols. Excellence in medium voltage work requires both.

Crucial Safety Protocols

The immense energy in medium voltage systems can cause catastrophic arc flash incidents, making strict safety protocols non-negotiable. Medium voltage electrical contractors follow life-saving measures that far exceed those for typical electrical work. Key protocols include:

- Arc Flash Technology: We install modern switchgear and protective devices designed to detect and suppress electrical arcs before they can release their full energy.

- Specialized Personal Protective Equipment (PPE): Our electricians wear arc-rated clothing, insulated gloves, and face shields specifically rated for high voltage work.

- Lockout/Tagout (LOTO) Procedures: We follow rigorous LOTO procedures to de-energize and physically lock equipment in the off position, preventing accidental re-energization.

- Method of Procedure (MOP): For complex operations, we develop detailed MOPs that outline every step, safety check, and contingency plan to ensure nothing is overlooked.

- Continuous Worker Training: Safety training never stops. We provide annual refreshers on safe work practices and lifesaving skills like CPR and First Aid.

At Lighthouse Energy, our exemplary safety record is a result of a culture that prioritizes safety above all else.

The Role of Technology in MV Projects

While safety protocols protect our people, technology helps us work smarter and more accurately. We leverage the latest advances to deliver better results for our clients.

- State-of-the-Art Test Equipment: We use tools like Very Low Frequency (VLF) testers and partial discharge detectors to assess cable integrity and identify developing problems without damaging equipment.

- Power Quality Monitoring: These systems track voltage fluctuations and harmonic distortion in real-time, allowing us to optimize performance and prevent premature equipment failure.

- Infrared Thermography: Thermal imaging cameras allow us to “see” heat patterns, identifying loose connections or failing components before they cause an outage.

- Project Management Software: Digital platforms provide real-time updates and centralized documentation, ensuring seamless communication and coordination.

- Drone Inspections: For overhead lines, drones equipped with high-resolution and thermal cameras allow for safe and efficient inspection of hard-to-reach equipment.

The combination of advanced safety and technology allows us to tackle complex projects more safely and efficiently than ever before. View our past projects to see how we’ve applied these principles for facilities across South Florida.

Understanding Medium Voltage Projects: Scope, Challenges, and Solutions

Every medium voltage project, whether an expansion or an upgrade, is a significant investment that demands expert execution and a commitment to long-term reliability. At Lighthouse Energy, we guide clients throughout Palm Beach County through these complex undertakings, protecting their operations, people, and bottom line.

Typical Project Scopes and Challenges

Medium voltage projects are complex, and mistakes are costly. Common project scopes include:

- Substation Expansion and Rehabilitation: These intricate projects adapt substations to facility growth or aging equipment. The primary challenge is integrating new technology with existing infrastructure, often while maintaining power.

- Switchgear Replacement: We replace outdated equipment with modern switchgear that includes advanced arc flash protection. For facilities that can’t afford downtime, we design and install temporary power systems to keep operations running during the transition.

- Underground Cable Replacement: Replacing aging underground cables involves careful excavation, directional drilling to minimize disruption, and flawless splicing work to prevent future failures.

A challenge is minimizing operational downtime. We carefully plan projects to occur during off-hours or in carefully orchestrated phases to ensure critical facilities in Boca Raton, Fort Lauderdale, Jupiter, Miami, and West Palm Beach continue to operate without interruption.

Ensuring Reliability Through Proactive Maintenance

The best repair is the one you never have to make. A well-maintained medium voltage system lasts longer, performs better, and provides peace of mind. Proactive maintenance is key to reliability.

- Regular Inspections: Our technicians conduct visual and technical assessments, using advanced diagnostic equipment to check for damage, wear, and thermal stress. This catches small problems before they become big ones.

- Extending Equipment Lifespan: Proper maintenance through regular cleaning, lubrication, and testing protects your investment by delaying expensive replacements.

- Ensuring Continuous Power: For businesses where downtime equals lost revenue, a regular maintenance schedule is essential for preventing failures. We recommend at least a yearly service evaluation, with more frequent inspections for critical facilities.

At Lighthouse Energy, we develop maintenance plans customized to your system and operational needs. To discuss your project or schedule a maintenance consultation, please contact us for a project consultation.

Conclusion

The medium voltage systems humming in the background of hospitals and manufacturing plants are what keep our modern world running. As we’ve explored, managing these systems requires medium voltage electrical contractors—highly trained specialists who understand the immense risks and complexities involved. At these power levels, there is no room for error, as a single mistake can lead to catastrophic failures and costly outages.

The stakes are too high to trust this work to anyone but specialists. From design and installation to safety protocols and emergency response, their expertise is something general electricians simply don’t possess. Having a qualified team on call can be the difference between a minor issue and a facility-wide shutdown.

Here at Lighthouse Energy, we understand these challenges intimately. When you call us, you’re not just asking for an electrician—you’re asking for peace of mind. That’s why we’re available 24/7 with qualified electricians ready to respond across Boca Raton, Fort Lauderdale, Jupiter, Miami, West Palm Beach, and all of South Florida.

Our approach is straightforward: no hidden fees, no runaround, just prompt professional service that gets the job done right the first time. We know your facility can’t afford downtime.

Whether you’re planning a major expansion, replacing aging equipment, or establishing a proactive maintenance program, we’re here to help. For comprehensive and safe power solutions for your facility, explore our commercial electrical services.

The lights staying on might seem like magic, but it’s really just good engineering, rigorous training, and a commitment to doing things right. That’s the Lighthouse Energy difference.