Why Industrial Control Wiring is the Backbone of Modern Manufacturing

Industrial control wiring is the network of electrical connections that powers, protects, and coordinates the machinery in factories and industrial facilities. It connects power supplies, PLCs, motors, sensors, and safety devices to create the automated systems that drive modern manufacturing.

An industrial control panel acts as the brain of a facility’s electrical system. Correct wiring allows technicians to quickly trace circuits, identify problems, and minimize downtime. Poor wiring, however, turns simple maintenance into a nightmare of tangled, unlabeled wires.

The stakes are high. Electrical failures in manufacturing can cost $10,000 per hour in downtime. As the industrial control market grows towards a projected $37.8 billion by 2030, the importance of this foundational work only increases. Yet, wiring is often treated as an afterthought, leading to circuit interference, overheating, and wasted hours during emergencies.

I’m Bruce Kemp, an electrical contractor specializing in industrial control systems. My experience has shown me that proper industrial control wiring is the key difference between a system that runs reliably for decades and one that causes constant headaches.

The Building Blocks: Core Components and Principles

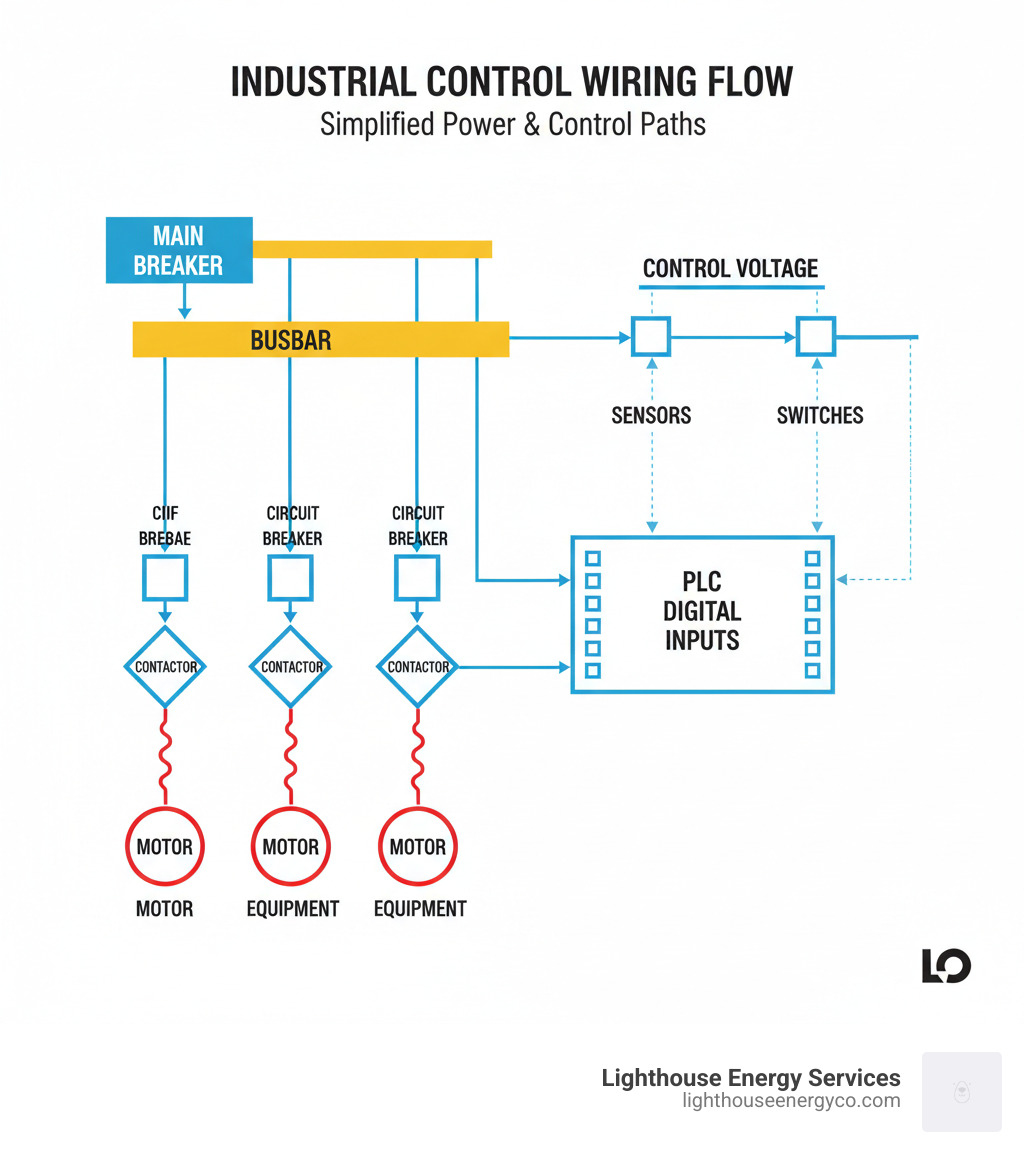

Understanding industrial control wiring begins with its core components. A well-designed control panel is a collection of devices working in concert.

Key Components Involved in Industrial Motor Control Systems

At the heart of modern automation are Programmable Logic Controllers (PLCs), the brains that process sensor data and send commands. Contactors and relays act as the muscle, using low-power signals from the PLC to switch high-power loads for industrial motors. Stable power is provided by power supplies (SMPS), which convert AC to the steady DC voltage required by sensitive electronics.

Organization is handled by terminal blocks, which create clear, accessible connection points that simplify troubleshooting. For protection, circuit breakers are the first line of defense, tripping during an overcurrent or short circuit to prevent damage and fires. Busbars efficiently distribute power throughout the panel, reducing wire clutter. Finally, the wiring connecting sensors and actuators on the factory floor to the PLC is critical for system operation. At Lighthouse Energy Co., we integrate all these pieces into reliable industrial control systems. See our services to learn how we can meet your industrial electrical needs.

Fundamental Principles of Industrial Control Wiring

Professional installation follows several core principles. The most fundamental is separating high-current power circuits from low-voltage control circuits to prevent interference and ensure safety. In control circuits, maintaining signal integrity is crucial; electrical noise can cause false readings, so we use careful cable selection, grounding, and routing. Voltage separation—physically separating different voltage levels (e.g., 480V from 24V)—is non-negotiable to protect components and personnel. Finally, understanding wiring diagrams is essential. Single-line diagrams (SLD) provide a high-level system overview, while ladder diagrams (LD) detail the logical sequence of control circuit operations for programming and troubleshooting.

The Critical Role of Grounding and Safety Circuits

Safety is paramount in industrial control wiring. Effective grounding and robust safety circuits form the foundation of a safe system.

Grounding provides a safe path for fault currents, preventing shock and protecting equipment. Best practices include using a dedicated grounding busbar and routing ground wires separately to avoid interference. We design single-point grounding systems to prevent ground loops, which can introduce electrical noise. Proper grounding ensures both human safety and equipment protection.

Safety circuits are specialized, independent circuits designed to prevent hazardous conditions. Safety relays monitor devices like emergency stop buttons and light curtains, ensuring machinery enters a safe state if a hazard is detected. These relays can even detect wire breaks. The wiring for emergency stop buttons must be fail-safe and independent of other controls. When wiring safety circuits, the cardinal rule is that any failure must cause the system to default to a safe condition. We adhere strictly to NFPA 79 guidelines because it’s the right way to ensure safety. You can learn more about how safety relays work to understand the technology.

Mastering Industrial Control Wiring: Best Practices for Panel Layout

A thoughtfully laid out control panel is understandable, easy to troubleshoot, and simple to maintain. Proper industrial control wiring isn’t just about connecting components; it’s about creating a functional system that can cut troubleshooting time by up to 50%. A disorganized panel leads to wasted hours and repeat service calls. See examples of our organized approach in our Gallery.

Wire Routing, Bundling, and Management

Neatness in wiring is about function and maintainability.

We follow several key principles for wire management. Wires should follow logical paths, typically top-to-bottom. Cable trays and ducts are essential for organizing wires, protecting them from damage, and allowing for heat dissipation. We incorporate “service loops”—small coils of extra wire—to provide enough wire slack for future maintenance without creating a tangled mess. We also respect the minimum bending radius of each wire to prevent conductor damage and protect wires from sharp edges with grommets. Following standards like the NFPA 79 guidelines ensures panel longevity.

Wire Numbering, Labeling, and Color Coding

Clear identification is non-negotiable for an efficient, maintainable system. A panel with unlabeled wires is a maintenance disaster.

Every wire and component in our panels receives a unique identifier that corresponds directly to the electrical schematics. This allows technicians to locate specific circuits in seconds. We use durable labels that resist heat, oil, and abrasion to ensure they remain legible for the life of the panel. Color coding provides instant visual information about a wire’s function and voltage, reducing human error and speeding up diagnostics. Consistent color coding, guided by resources like Rockwell Automation’s advice on wire colors used in control circuits, makes a panel safer and easier to service.

Best Practices for Wire Termination

A poor termination is a failure waiting to happen. The point where a wire connects to a device is a common source of high resistance, heat, and eventual failure in industrial control wiring.

Secure connections must be both mechanically and electrically sound. This means using torque screwdrivers for screw clamp terminals and proper tools for crimped connections. For stranded wire, ferrules are a game-changer. These small metal tubes are crimped onto the wire end to contain all the fine strands, preventing fraying and ensuring a solid, low-resistance connection. In high-vibration environments, ferrules dramatically reduce the chance of loose connections. As some say, if a thread of stranded wire breaks, it’s a problem, but ferrules prevent that break from happening. Using the right termination tools is not an area to cut costs; it’s an investment in reliability.

Standards, Selection, and Advanced Considerations

Beyond technical skill, industrial control wiring demands adherence to standards and smart material selection. A well-built panel that ignores codes or uses the wrong wire type is destined for trouble. At Lighthouse Energy Services, we prioritize compliance and proper selection to build systems that last. Learn more About Lighthouse Energy Co. and our approach.

Navigating Industry Standards and Regulations

Industry standards are a roadmap to a safe, reliable system, based on decades of learned lessons. In North America, the National Electrical Code (NEC) or NFPA 70 is the primary guide, covering everything from wire sizing to grounding. We pay close attention to Article 409 on wire spacing in control panels. You can find the standard at the National Electrical Code (NEC) website.

UL 508A is specific to industrial control panels, detailing component selection, wiring methods, and Short-Circuit Current Ratings (SCCR). Internationally, IEC standards like IEC 60947 are key. For machinery, NFPA 79 provides detailed electrical standards. The increasing harmonization between UL and IEC standards simplifies compliance for global equipment.

| Standard | Primary Focus | Geographic Scope | Key Aspects |

|---|---|---|---|

| NEC (NFPA 70) | General electrical wiring and equipment installation | North America | Wire sizing, overcurrent protection, grounding, clearances |

| UL 508A | Industrial Control Panels | North America | Component selection, SCCR, wiring methods, enclosure types |

| IEC 60947 | Low-voltage switchgear and controlgear | Global (especially Europe) | Component specifications, performance, safety |

| NFPA 79 | Electrical Standard for Industrial Machinery (<= 600V) | North America | Wiring methods, conductor sizing, protection, operator interface |

Key Considerations for Industrial Control Wiring Selection

Choosing the right wire affects system performance and longevity. For most industrial control panels, flexible stranded wire is superior to rigid solid wire because it withstands vibration and mechanical stress without cracking.

Wire gauge (AWG) must be correctly sized for the current to prevent overheating and voltage drop; we typically use 14 AWG or larger for power conductors. The insulation material is equally important. While standard PVC is common, materials like Machine Tool Wire (MTW), PTFE, or silicone rubber are chosen based on the panel’s temperature rating and exposure to environmental factors like oil, chemicals, or moisture.

Mitigating Electromagnetic Interference (EMI)

Even with perfect wiring, electromagnetic interference (EMI) can cause system malfunctions. EMI is generated by devices like motors and VFDs and can induce “noise” in adjacent wires, leading to false sensor readings and communication errors.

The first line of defense is to keep power and signal wires separated. For sensitive analog or communication lines, shielded cables are used to block external noise; the shield must be properly grounded at one end to be effective. Proper grounding provides a path for electrical noise to dissipate safely. For differential signals, twisted pair wiring is effective, as it allows for common-mode noise cancellation at the receiver. Ignoring EMI leads to intermittent faults and costly downtime.

Frequently Asked Questions about Industrial Control Wiring

We’ve answered countless questions about industrial control wiring over the years. Here are some of the most common ones.

What are the most common pitfalls to avoid in control panel wiring?

The most frequent and costly mistakes we see are:

- Improper wire sizing: Using wires too small for the current load causes overheating and voltage drop.

- Inadequate spacing: Crowding power and signal wires together leads to EMI and heat issues.

- Poor grounding: Creating ground loops or failing to use a dedicated ground bus compromises safety and reliability.

- Inconsistent labeling: Unlabeled or poorly labeled wires and components make troubleshooting a nightmare.

- Neglecting service loops: Leaving no extra wire slack makes future maintenance or modifications difficult.

- Improper terminations: Forcing multiple wires into a single terminal or using incorrect tools creates loose connections that will fail.

What is the difference between a wiring diagram and a schematic?

It’s a crucial distinction. A schematic diagram shows the logical function of a circuit—what it does. It uses standard symbols to illustrate the electrical relationships between components. A wiring diagram shows the physical layout and connections—how to build it. It guides the actual installation, showing wire runs and terminal numbers inside the panel. You need both for quality work.

Why are ferrules important for stranded wire?

Ferrules are essential for creating reliable connections with stranded wire. When you insert bare stranded wire into a terminal, the fine strands can fray, break, or miss the connection point, leading to high resistance or short circuits. A ferrule is a small metal sleeve crimped onto the wire’s end that:

- Bundles all strands into a solid pin.

- Prevents fraying and ensures a complete electrical connection.

- Reduces resistance and prevents hot spots.

- Protects the wire from mechanical damage during insertion.

In high-vibration industrial settings, ferrules are critical for preventing loose connections, a leading cause of equipment failure. Their use is a hallmark of a professional, long-lasting installation.

Conclusion

Industrial control wiring is more than connecting points; it’s the foundation of a safe, reliable, and efficient industrial operation. From separating power and control circuits to implementing proper grounding, labeling, and termination techniques, every detail matters. Following standards like NEC and UL 508A isn’t red tape—it’s an investment in long-term performance and protection against costly downtime.

Even the most advanced automation software is useless without a solid wiring infrastructure. When done right, it enables quick diagnostics and smooth maintenance. When done wrong, it leads to mystery failures and safety hazards.

Choosing the right partner is critical. You need an expert who understands that industrial control wiring is both a science and an art. At Lighthouse Energy Co., we deliver that expertise. We serve clients throughout South Florida—from Boca Raton and Fort Lauderdale to Jupiter, Miami, and West Palm Beach, covering all of Palm Beach, Broward, and Miami-Dade Counties. Our qualified electricians are available 24/7, with no hidden fees, to get the job done right. We don’t just wire panels; we build the reliable backbone for your operation.

Your industrial facility deserves electrical infrastructure you can count on.